METAL HYDRID HYDROGEN STORAGE TECHNOLOGY

MASTERING THE SYSTEM INTEGRATION

CONTAINING THE VOLATILE HYDROGEN ATOM

Hydrogen will be the main fuel of the future. It can be used directly or as a reactant to produce derived fuels. While hydrogen contains a lot of energy per mass, it is a light and volatile gas and is thus very hard to contain and store. For this reason, GRZ Technologies has advanced a technology that allows safely and compactly storing hydrogen at low pressures: metal hydrides.

THE FUEL OF THE FUTURE

Hydrogen contains 33.3 kWh per kg of energy, measured as a lower heating value. This is about 3 times more than petrol. However, hydrogen is also very light:

One cubic meter of Hydrogen at standard conditions contains only 0.09 kg of hydrogen. For this reason, the storage of hydrogen requires compression to high pressures or liquefaction – in both cases, a challenging and costly task. The alternative is to use a carrier material that absorbs hydrogen like a sponge. Thereby, the process in which hydrogen enters the carrier material is called absorption and the process in which it is taken out of the carrier material is called desorption.

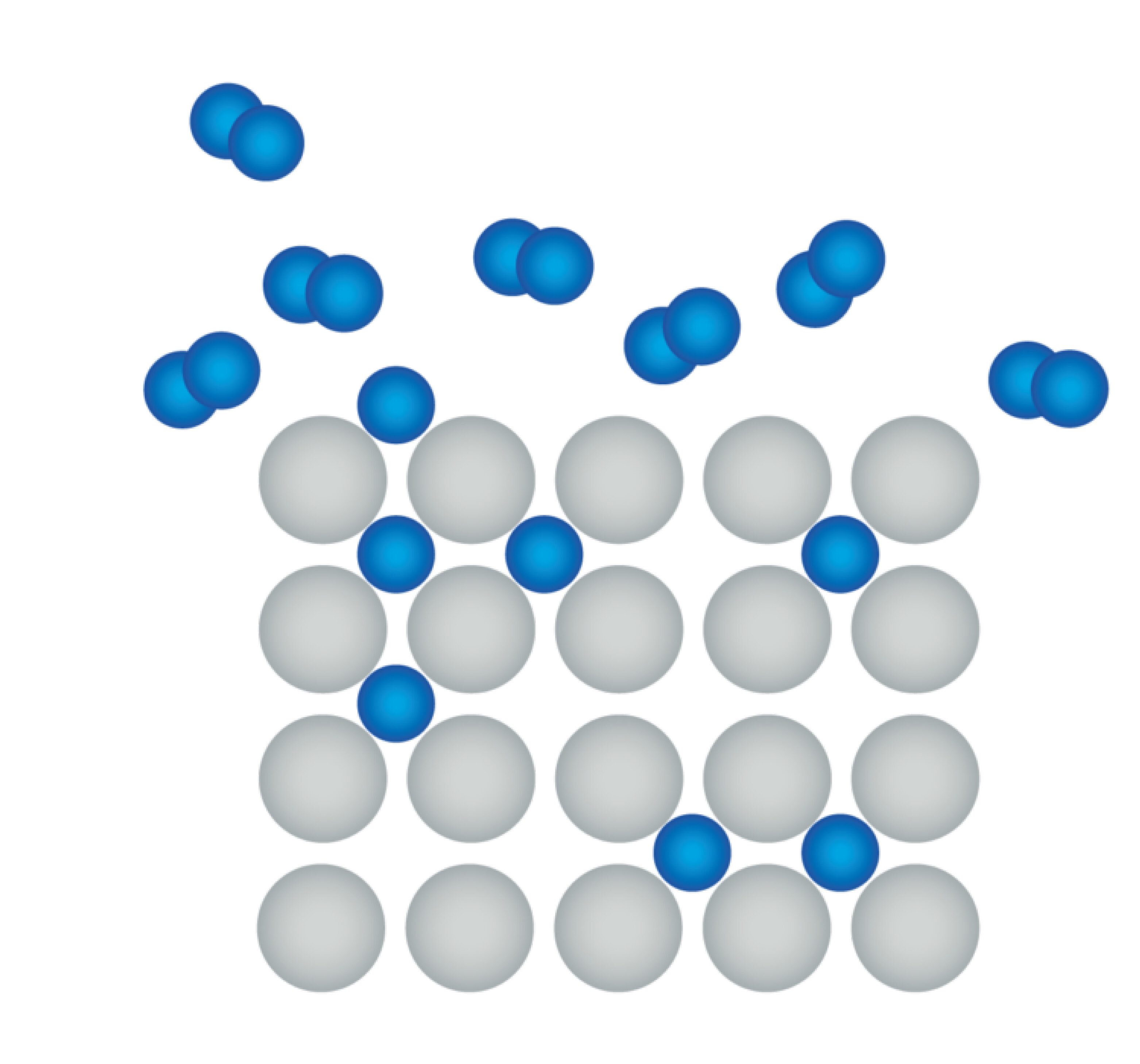

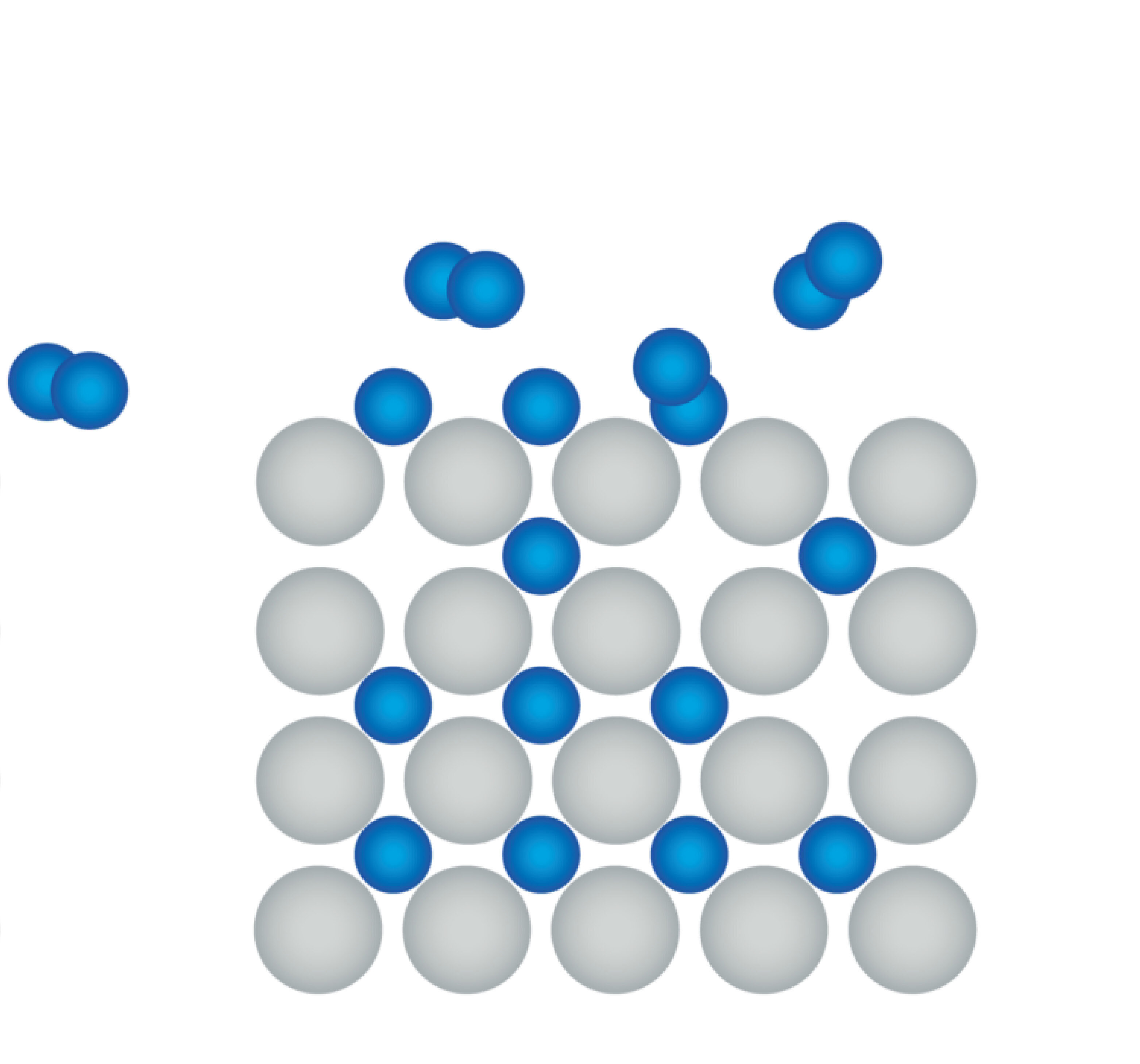

Absorption of hydrogen: When hydrogen gas is exposed to a metal hydride, it is absorbed by the metal atoms in the form of hydrogen atom. The hydrogen atoms then diffuse through the metal lattice and are trapped within the metal structure.

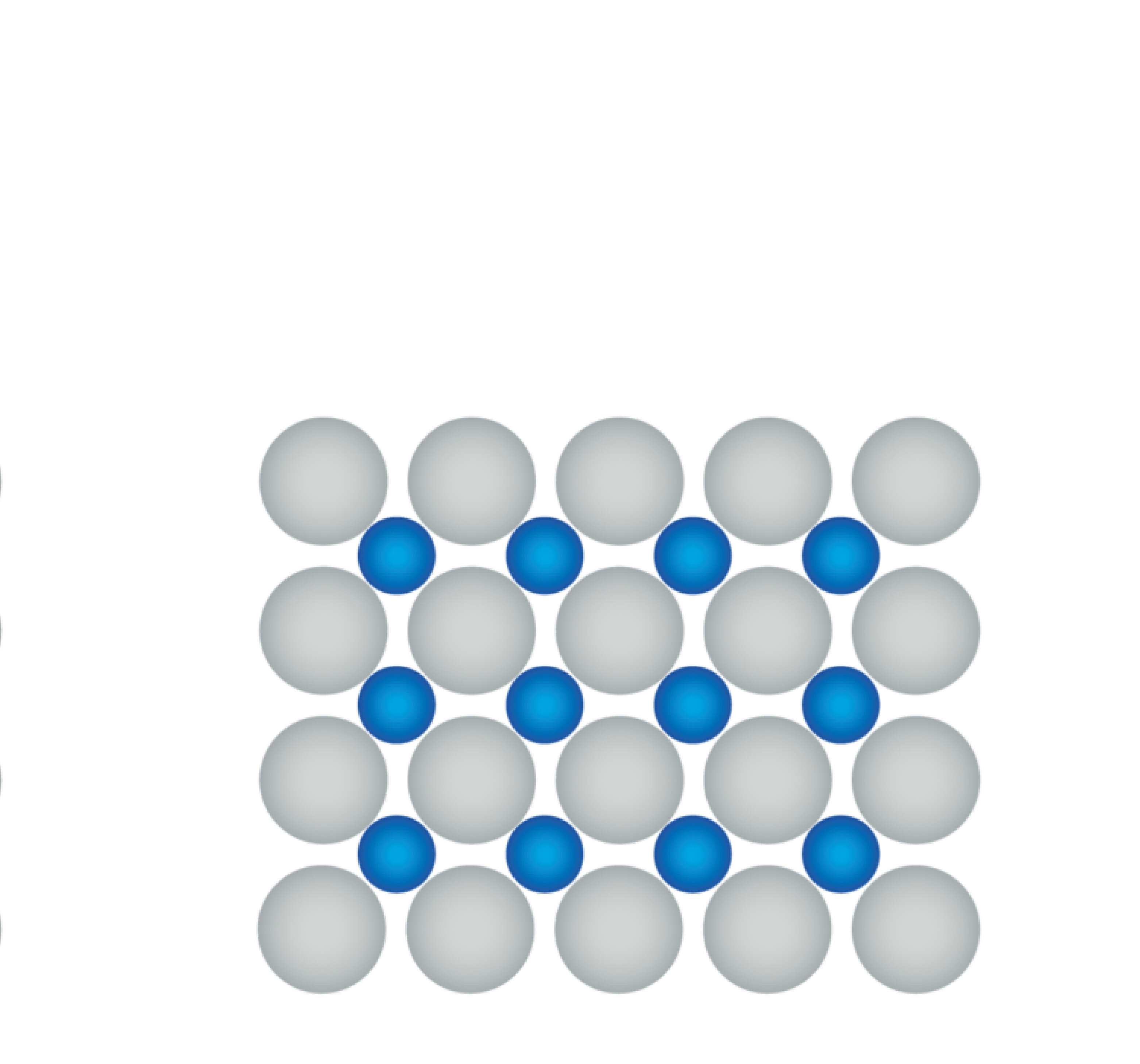

Desorption of hydrogen: When the metal hydride is heated or exposed to a lower pressure, the hydrogen atoms are released from the metal lattice and can be used for downstream processes such as a fuel cell, for example.

The absorption and release of hydrogen in metal hydrides are fully reversible processes and can be repeated many times without degrading the metal hydride material. Metal hydrides have several advantages as hydrogen storage materials, including high storage capacity, excellent safety properties, and low environmental impact.

SOLID-STATE HYDROGEN TECHNOLOGY

Metallic carrier materials for hydrogen have been known for a long time. Pioneering research was done by GRZ Technologies’ co-founder, Prof. Andreas Züttel in the 1990’s. Continuing on that path, GRZ has invested into the industrialization of the solid-state hydrogen technology and uses it for two principal applications: storage and compression of hydrogen.

MASTERING SYSTEM INTEGRATION

While the knowhow on the carrier materials is crucial, it is not sufficient by itself. High-performance solid-state hydrogen systems are carefully engineered plants balancing thermal properties, material characteristics, pressure vessel design, and control systems. For this reason, GRZ Technologies has specialized engineering teams collaborating closely together to create the best possible product.